Since the tragic event at Grenfell Tower in June 2017 there has been a great deal of work carried out to identify buildings that are clad with unsafe products.

A2O got involved at a very early stage in building BS8414 test rigs at the BRE to determine whether a current build-up is appropriate and if an intended installation will pass.

Since then A2O has worked on numerous facade remediations as Specialist Facade Subcontractor and as Principal Contractor. Here is an overview of the key areas:

A2O Internal Controls include use of Dalux, Bolster and A2O’s own extensive set of Custom Forms, carried out by dedicated QA Managers on all large projects covering:

A2O’s trusted consultants External Inspections which cover Health & Safety, Fire Engineering, Structural Integrity and issues unique to each project.

Watch this 1min video here for highlights, or the 5min video for more insight.

In addition to the Case Studies below, we are currently recladding multiple residential buildings in London, throughout the South East and increasingly in the South West.

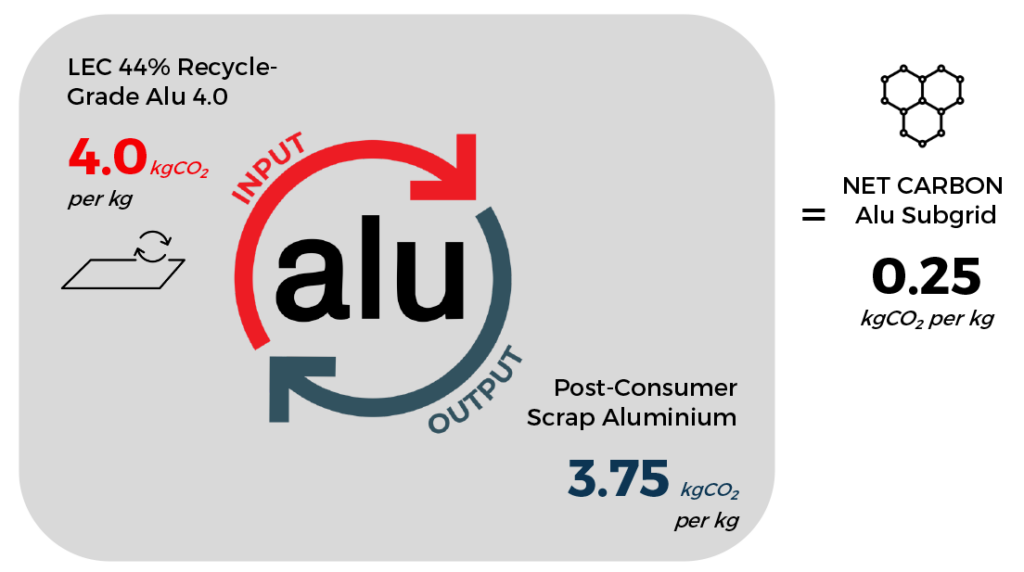

In partnership with RJ Facade Systems and Hydro, A2O now installs subgrids in LEC (low embodied carbon) Recycle Grade 4.0 aluminium. This reduces carbon emissions by over 40% compared to standard European aluminium.

On facade remediations where A2O is principal contractor, the aluminium reclad strip can be collected and recycled, slashing the subgrid’s carbon footprint by over 93%.

See Aluminium Closed Loop Case Study:

Registered in England 4344380